What is peracetic acid?

Peracetic acid is used as an extremely strong and effective oxidizing agent in a wide range of applications. It reliably and permanently kills pathogens, bleaches, cleans and disinfects. Despite its high efficacy, it is a sustainable chemical. You can read about what peracetic acid is, how it is produced and why it is sustainable here.

Peracetic acid (or peroxyacetic acid, PAA) is a peroxide and a colorless, liquid mixture of hydrogen peroxide and acetic acid (vinegar). Its chemical formula is C2H4O3. Peracetic acid is a sustainable chemical, because its decomposition produces only water, oxygen and very biodegradable acetic acid and no environmentally harmful substances.

Peracetic acid is a very powerful oxidizing agent that is very effective, even in low concentrations and at low temperatures, at killing bacteria, fungi, spores and viruses – it even works against the Corona virus. By comparison, you need a hundred times as much hydrogen peroxide to achieve the same effect. Germs also cannot develop any resistance mechanisms against peracetic acid, so it remains effective.

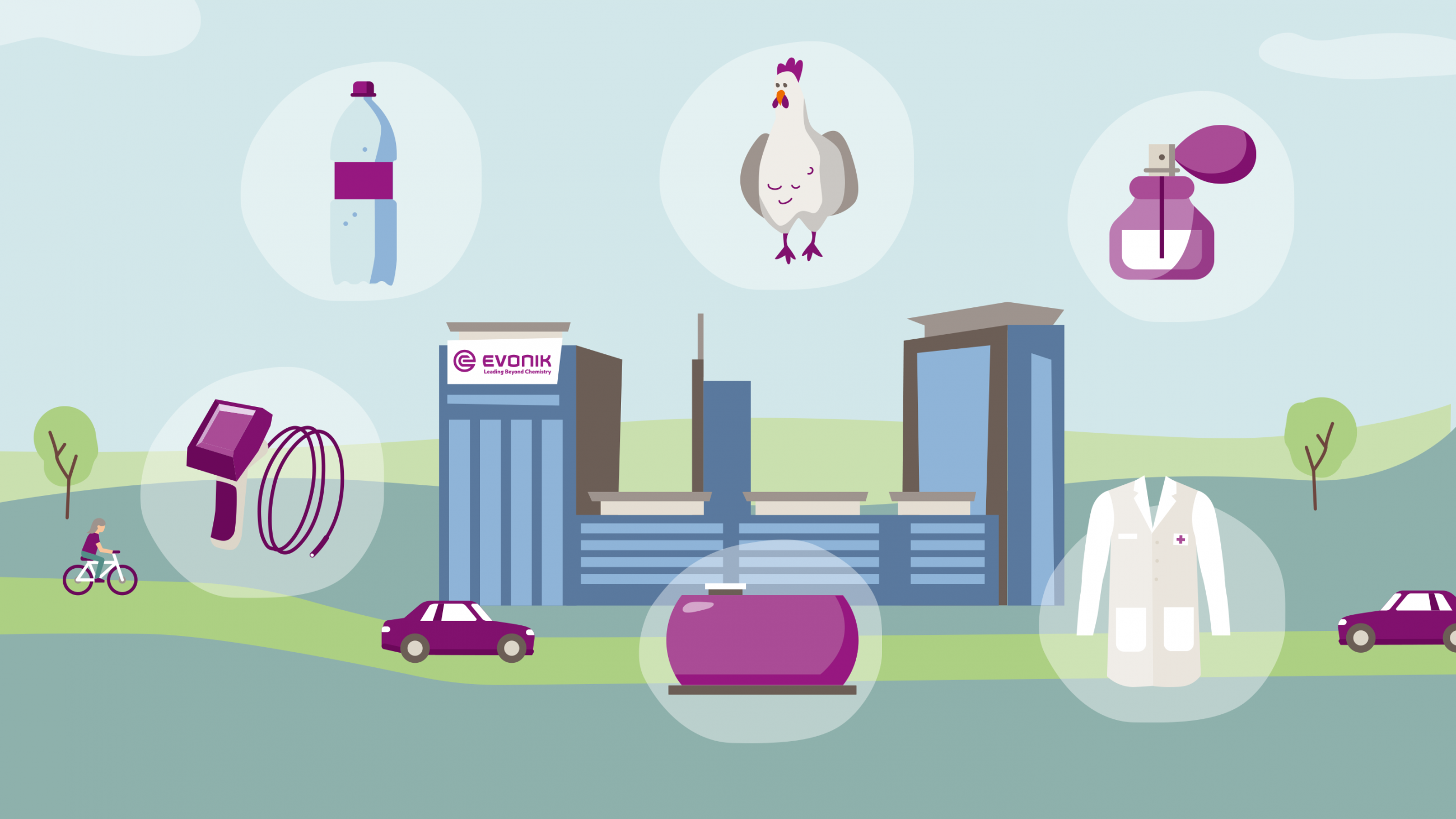

Given all these advantages, peracetic acid is used in many sectors of industry for disinfection and sterilization purposes and also as a bleaching agent. The spectrum of applications ranges from the food industry to environmental applications, such as wastewater treatment and soil remediation.

Peracetic acid is available as a so-called equilibrium mixture of peracetic acid, hydrogen peroxide, acetic acid and water in concentrations of 5 to 40 percent. When contaminated and at higher temperatures, there is a risk that it will decompose. Evonik Active Oxygens therefore ensures that the chemical is only packaged, stored and transported in clean containers made of appropriate materials.

How is peracetic acid produced?

Peracetic acid is produced from the raw materials, hydrogen peroxide and acetic acid. In a so-called autoxidation process, the hydrogen peroxide is first produced from hydrogen and oxygen. This happens in three steps: first, hydrogen is added to a working solution and combines with this reaction medium. The second step involves atmospheric oxygen being pumped into the working solution under pressure, producing hydrogen peroxide. This is then extracted with the addition of water.

The hydrogen peroxide is then mixed with acetic acid and additional additives and treated further. Increasing use is being made here of acetic acid from renewable raw materials.

Why is peracetic acid sustainable?

Peracetic acid offers many sustainability benefits. First, it decomposes into environmentally compatible substances such as water, oxygen and vinegar after use, and toxic byproducts are not generated. Its wide range of applications and potency, even at low dosages, also make this biocide particularly resource-efficient.

Peracetic acid …

- … treats and purifies municipal wastewater in an environmentally compatible way, while it disinfects reliably and is effective even in small quantities.

- … has a broad range of antimicrobial effects and is therefore highly efficient at surface treatment in the food industry, as well as in the medical and industrial sectors.

- … reduces contamination with pathogenic bacteria such as salmonella, campylobacter and E.coli when food is being handled. Peracetic acid reduces bacterial contamination that can cause product spoilage. Certain grades are approved for organic processing.

- … disinfects animal hygiene surfaces and equipment and therefore prevents animals catching diseases.

- … reliably kills bacteria and germs inside plastic bottles without leaving residues. The quality of beverages is not affected, consumers get a safe, long-lasting product.

- … works extremely effectively in a variety of environments while meeting the bleaching and disinfection requirements of industrial, institutional and private consumers and laundries.