What is hydrogen peroxide?

Many people associate hydrogen peroxide with hair bleaching. But it can do much more: this green chemical is used as an effective oxidizing agent in a wide range of sectors and industries. Here’s what hydrogen peroxide is, how it’s produced, and why it’s a sustainable product that has the potential to replace less sustainable chemicals.

Hydrogen peroxide is a colorless, liquid compound of hydrogen and oxygen with the chemical formula H2O2. The chemical has been known for more than 200 years, yet it is more up-to-date and in demand than ever before. This is because hydrogen peroxide is a completely natural, green product that occurs naturally, for example, in rainwater or snow, and even in the human body. When it decomposes, only water and oxygen are produced; there are no environmentally harmful byproducts. This special property makes hydrogen peroxide particularly valuable in times of increased environmental awareness.

Hydrogen peroxide is a powerful oxidizing agent that many people associate primarily with dying hair blond. The bleaching effect of hydrogen peroxide is harnessed here. But it can do so much more. Hydrogen peroxide has a disinfectant, antibacterial effect and eliminates odors, which is why it can be used as a cleaning agent at home, and also to disinfect wounds.

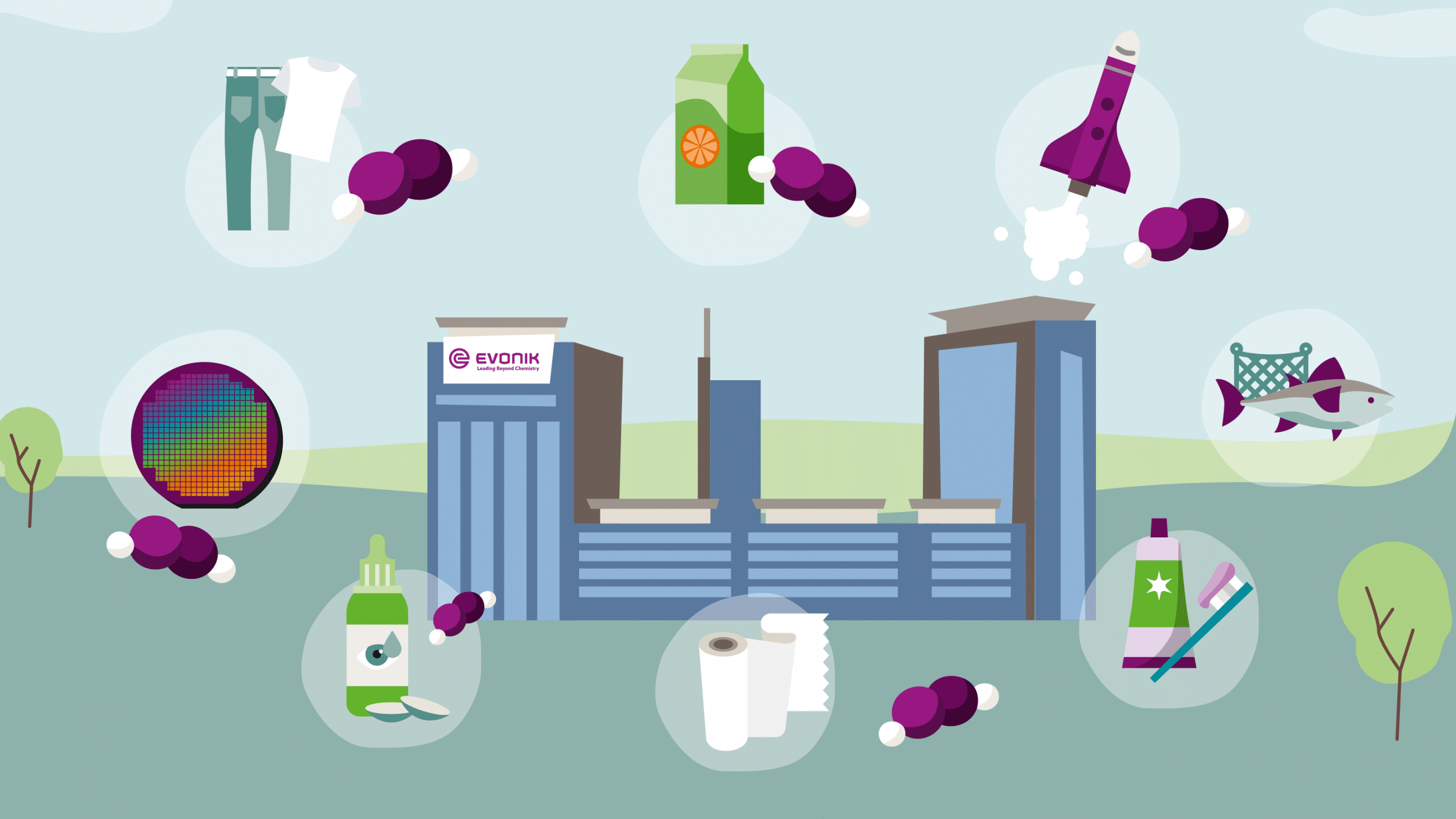

However, the versatile green chemical is in particularly high demand in a wide range of industrial sectors — from the paper industry to the food, pharmaceutical and cosmetics industries, and even in electronics. Hydrogen peroxide is also increasingly used in (waste) water treatment, as a reagent in chemical syntheses and even as rocket fuel.

Hydrogen peroxide is produced for industry in concentrations ranging from 3 to as much as 98 percent. Depending on the application, the chemical is used either alone or in combination with other substances such as iron ions, UV radiation or ozone, in which case it has an even more powerful effect.

How is hydrogen peroxide produced?

Hydrogen peroxide is primarily produced from hydrogen and oxygen in the so-called autoxidation process. The key element of this process is the so-called working solution in which the reactions take place. The process consists of three steps: hydrogenation, oxidation and extraction.

First, hydrogen is added to the working solution and combines with this reaction medium. The second step involves atmospheric oxygen being pumped into the working solution under pressure, producing hydrogen peroxide. This is then extracted with the addition of water. This produces a 35 to 50 percent aqueous solution, which can then be processed in several steps using steam, among other things.

Good to know: the working solution in the plant is the same at the end of the hydrogen peroxide production process as it was at the beginning. Therefore, it can theoretically be used indefinitely. However, to ensure that reactions proceed smoothly and safely, it must be purified regularly. Evonik’s oldest working solution dates from 1969 and is used at its Antwerp plant.

Why is hydrogen peroxide sustainable?

Hydrogen peroxide decomposes into water and oxygen once the application has been completed. Therefore, no toxic byproducts or coproducts that could harm people or the environment are generated. This unique chemical property makes hydrogen peroxide a sustainable chemical that can replace other, less sustainable chemicals in a range of applications.

Hydrogen peroxide …

- … treats and purifies municipal and industrial wastewater without the use of environmentally harmful disinfectants.

- … bleaches paper and pulp efficiently and in an environmentally compatible way and can also be used resource-efficiently in paper recycling.

- … rids beverage containers of bacteria without leaving residues or affecting the quality of these comestibles, and makes them last longer even without refrigeration.

- … is used as a feedstock in processes such as HPPO and HPPG in the sustainable production of globally in-demand materials, such as propylene oxide and propylene glycol.

- … helps to launch and in future to navigate satellites that can provide valuable data for sustainable applications on our planet through Earth observation.

- … cleans electronic components cost-effectively and without generating harmful waste products.

- … helps to produce foam and insulating materials in a resource-saving way, which in turn helps to save energy.

- … is used in the recycling of valuable materials, e.g. in the recovery of lithium from lithium-ion batteries.

- … and much more besides.